Our other sites:

Project Overview

Date Complete

2015

Sector

Commercial

Challenge

Locating a main supermarket within a dense residential area makes a great deal of sense in terms of serving consumers living in the local community. But it brings with it a unique set of considerations, not least shielding local residents from the noise associated with the running of a major mixed retail outlet. This was the conundrum faced by a leading supermarket in Leicestershire that is located in the middle of a flourishing housing development. Due to the setting of this supermarket there was a growing concern in relation to the unavoidable noise created by the constant flow of delivery vehicle traffic and movement of goods within the site.

architects working on this specific project recommended the installation of acoustic fencing, both around the perimeter of the staff car park that backs onto housing, as well as around the service yard where deliveries for the store are received. In addition, two new acoustic gates were required, one to span a 9m opening to enable HGV access to the main loading bays and an additional gate to provide authorised personnel with easy entry to the waste compactor.

er recognising the specialist and bespoke nature of the task in hand, the contractors and architects were keen to deliver a solution that met both the performance and aesthetic considerations of the project. A decision was made to contact Jacksons Fencing, who is not only the designer and manufacturer of the revolutionary “Jakoustic” acoustic barrier system, but as a company, is committed to working in partnership with architects, specifiers and contractors to deliver inventive solutions to site-specific problems.

Solution

Following an initial site visit by an Acoustic Engineer and Jamie Reeson, one of Jacksons regional Fencing Managers, the design team at Jacksons reviewed the outlined plans. There were a few concerns flagged up by the design team, the most significant of which related to the 4m high double automated swing gates for the 9m opening. This was decided to be unsuitable for the application as could be subject to high wind loading and potentially pose a health and safety risk. In addition, the gates would have failed to meet the required acoustic levels and represented a less than perfect solution in a situation where space was restricted.

The smaller gate that was to provide access to the waste compactor also required further deliberation. Initially suggested for the 3m opening was a single leaf automated gate, however it was thought that the opening would not be wide enough for easy skip manoeuvring. It was also put forward to have an outward automation, but this presented a safety risk to members of staff and public that had access to the area in front of the gate.

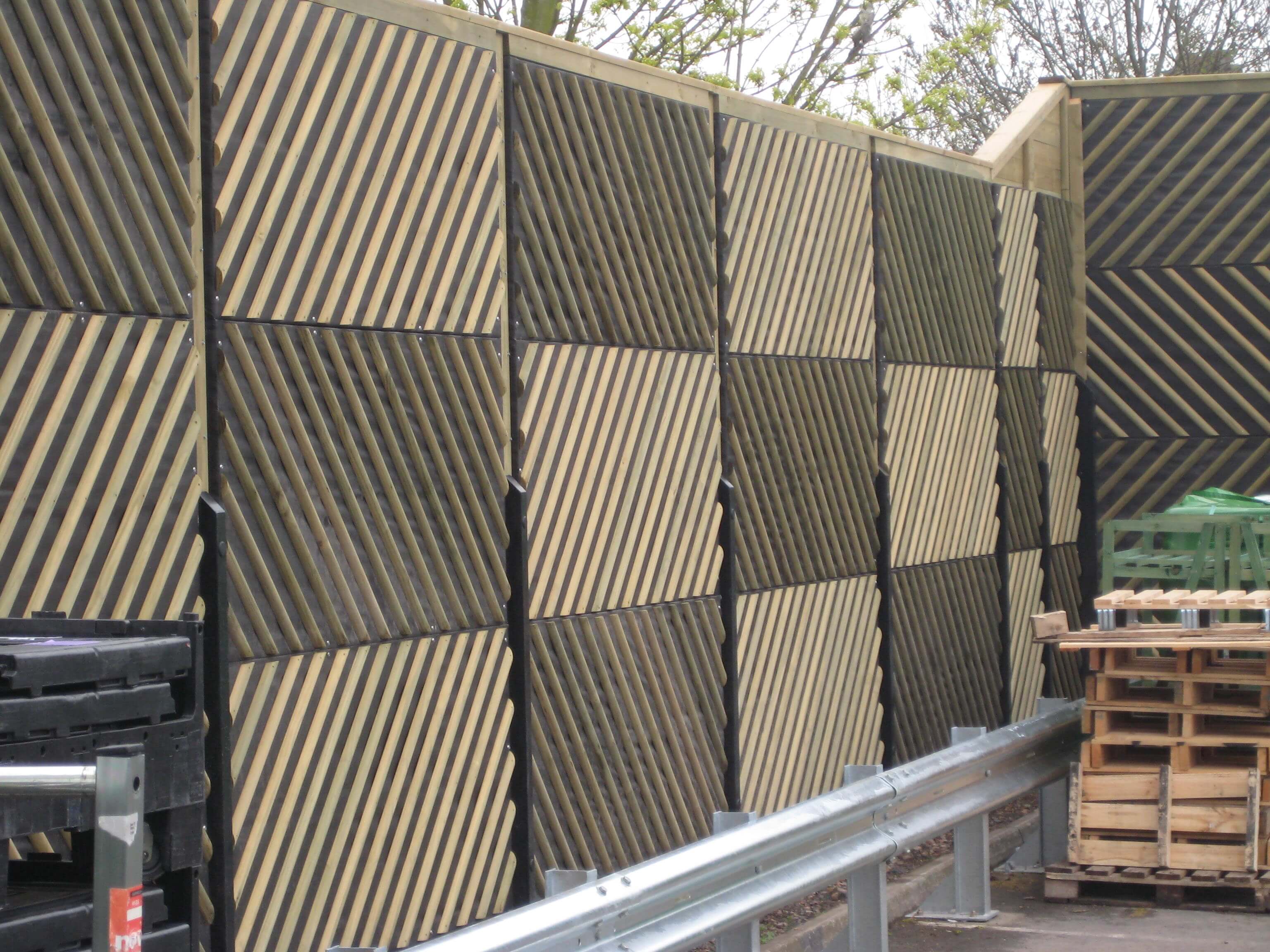

The Jacksons design team came up with solutions to these two problems. For the large gate that was needed for the 9m opening, a 4m high x 13.2m long sliding gate was designed and approved. This gate was likely to be one of the largest acoustic gates ever produced and was certainly not a standard construction. The single leaf automated swing gate that was to provide access to the waste compactor was replaced with a 4m high x 3.5m wide double leaf manually operated gate. Both these gates were constructed with the absorptive backing panels facing the loading yard and waste compactor to maximise the high levels of noise protection.

In addition to the creation of the two Jakoustic® gates and a compound of two-sided Jakoustic® fencing around the service yard, the project also involved the installation of 185m of 2.4m high Jakoustic® Reflective barriers to segregate the staff car park area from the neighbouring housing. Whilst the reduction of noise was the prime consideration, this element of the project also demanded considerable attention to detail in terms of delivering an attractive fence. Working on an uneven surface, the fencing had to be stepped and raked to accommodate the changing gradient and contours of the land. The attention to detail even extended as far as incorporating a mini Jakoustic® gate to enable a lamppost, to be lowered into the car park (to make it easier when replacing the lamp).

The entire installation took approximately 5 weeks to complete. It represents a major engineering feat achieved as a result of combining the skills of various specialists to deliver a highly effective, attractive fencing and access solution with no compromise on aesthetics or the operational effectiveness of the site. The efficacy of the acoustic barriers has been universally well received and numerous favourable comments have also been made on the attractive and natural appearance created by the new acoustic barriers.

Ready to find out more?

To discuss your requirements please call us or fill out the form below and someone from our sales team will be in contact with your quote shortly.

Request A QuoteRelated Products

Find related products for your order. If you cannot find the item you are looking for, please do not hesitate to call our friendly sales team.

Top