Our other sites:

Rigid Mesh Fencing and Security Mesh Panels

Rigid Mesh Fencing

Our wide range of Rigid Mesh Fencing systems all feature our unique, vandal proof, panel to post fittings and are suited to a range of applications, from general perimeter demarcation to high security sites.

All our Rigid Mesh Fencing is constructed from steel wire. Where most welded mesh fencing is simply hot dip galvanised, selected versions of our EuroGuard® range are zinc alloy coated for exceptional corrosion resistance.

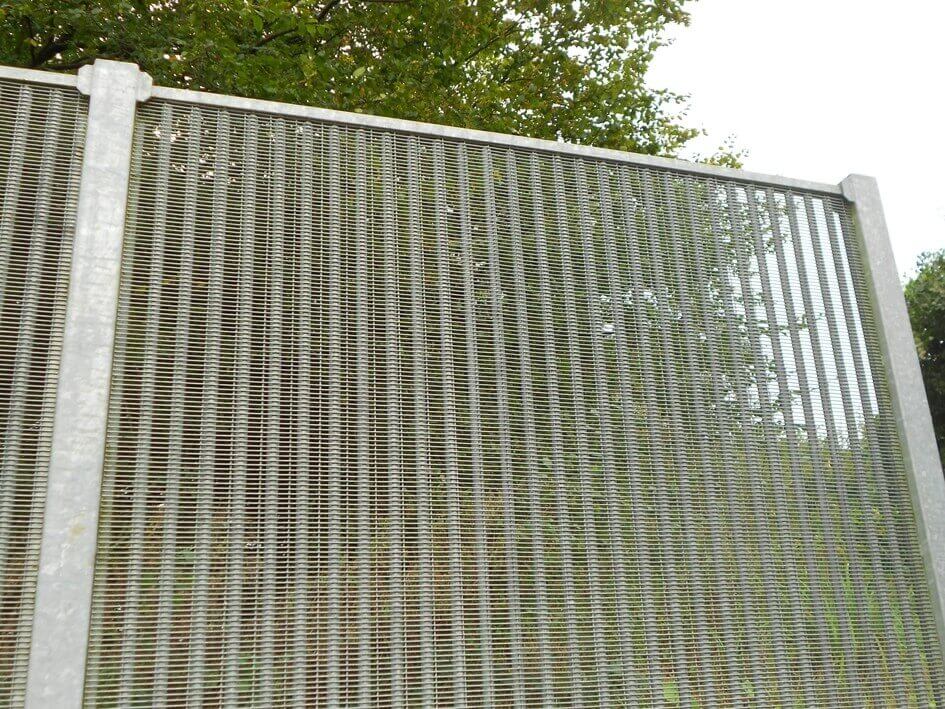

We manufacture a range of customisable welded mesh products suitable for all applications, from schools and sports facilities, to commercial properties and high security sites. Rigid mesh fencing offers high visibility and doesn't compromise CCTV. With posts adaptable for security toppings, cameras and lighting, flat profile designs for sports enclosures, reinforced 'V' mesh styles for additional strength, and close-knit panels for high security applications, we can offer you the tailored security solution your site requires.

View Our Welded Mesh Fencing Range

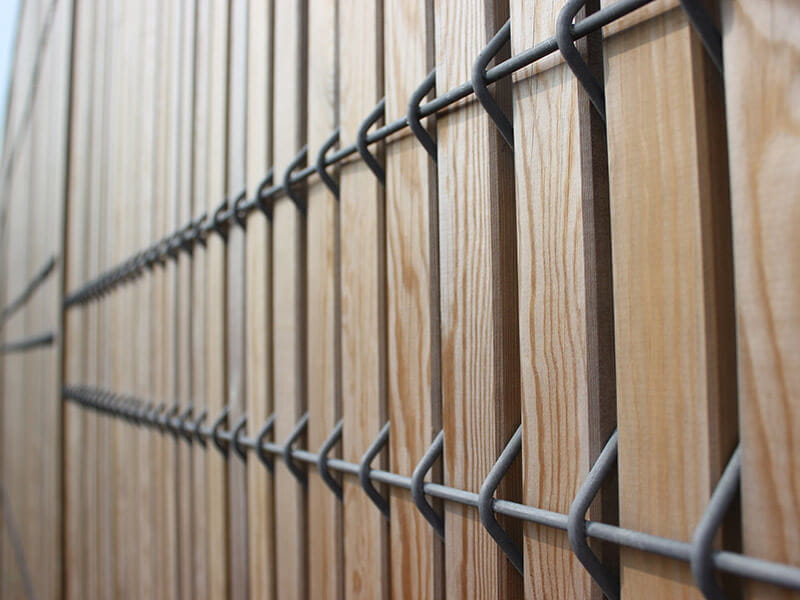

All our welded mesh panels feature our unique vandal proof panel to post connectors. Our EuroGuard® range includes a flat profile fence with horizontal twin wires suitable for schools and sports courts, reinforced V shape profiles for strength and rigidity, and steel and timber combinations to increase privacy and aesthetic appearance with a natural timber façade. Our Securi-Mesh® range employs a climb resistant heavy duty mesh with small apertures and welds, meeting specifications including the use of CCTV, and where a visual deterrent is a key consideration.

Why choose welded mesh fencing from Jacksons?

Welded mesh fencing lends itself to applications where good visibility, quicker installation speeds, and lower cost are primary requirements.

Looking at the most popular mesh designs, it’s easy to assume that there is little to choose between them; on paper, they look much the same and share similar wire spacings, reinforcing folds and wire sizes. But that’s far from the reality.

There are many factors that will distinguish a mesh panel fence capable of providing security and a long service life from those that can’t. Here are some points to consider if you want a welded mesh fence that will remain fit for purpose throughout a long life cycle:

QUALITY STEEL

All welded mesh fence panels start as coils of steel wire. As with all steel products, the quality and durability of the finished product results from starting with a good material, and that’s largely a factor of the wire manufacturing process. Where possible, check that the steel wire being used by the fence panel manufacturer is of a good grade to ensure consistency and adherence to material specification and tolerances.

WIRE DIAMETER (GAUGE)

Rigid welded mesh fence panels are almost always sold with a protective coating covering the wire – whether pre-galvanised (Galvanised Before Welding), Galvanised After Welding (GAW), Zinc-Alloy coated or plastic coated. Some manufacturers measure their wire diameters after the coating is applied. A smaller diameter wire with a heavier layer of coating will not provide the same structural strength and resistance to cutting as a product made from heavier diameter wire, even though both will be show as being the same diameter. Jacksons provides all of its wire mesh measurements as readings taken before coating, to provide an accurate representation of strength. The coating provides additional thickness on top of the measurement specified.

MESH PANEL COATING

ZINC GALVANISED BEFORE WELDING (PRE GALV)The mesh fence will be manufactured with wire that has been pre-galvanised with a zinc coating before being welded together. During manufacturing, each intersection of horizontal and vertical wires is welded to form the mesh panel. However, the welding process effectively removes the protective layer of zinc, leaving the wire unprotected and subject to corrosion at precisely the points where it needs to maintain its integrity.

ZINC GALVANISED AFTER WELDING (GAW)Rigid mesh fence panels galvanised with a zinc coating after the wires are welded into place are inherently more durable than panels manufactured from pre-galvanised wires. The manufactured panels are typically hot dip galvanised for full coverage of the zinc coating. The downside of this process is that it requires significant ‘fettling’ after manufacture to remove surface imperfections and sharp zinc spikes which adds to the cost.

ZINC ALUMINIUM ALLOY COATED BEFORE WELDING (GALFAN®)The notable exception to the rule is with panels manufactured with Galfan® or similar zinc alloy coated wire to British Standard (BS EN 10244-2:2009). The higher aluminium content of Galfan® coated wire allows the join to ‘heal’ under welding temperatures and as a result, maintain protection against corrosion.

Jacksons supplies both galvanised with a powder coating and Galfan® coated mesh fencing.

POLYESTER POWDER COATINGPolyester powder coating to British Standard BS EN 13438 is applied to a galvanised or zinc alloy coated substrate to provide a decorative finish in a virtually limitless range of colours. Additionally, powder coating enhances the durability of a mesh fence by providing a further protective layer. We have our own powder coating facility at our headquarters in Kent to ensure a high level of control and premium architectural grade finish.

THERMOSET COATINGSThermoset powder coatings (including polyester powder coating) are sprayed onto a galvanised or zinc alloy substrate and are particularly effective in applications where the fence is exposed to harsh or corrosive atmospheres, such as coastal areas, deserts, and industrial facilities. The combination of a thermoset coating on a galvanised substrate provides maximum surface protection to a mesh panel fence.

POSTS & FIXINGSPosts and the mechanical fixings of welded mesh panels to posts are essential to the safety and security characteristics of mesh fencing, and some manufacturers are happy to down-spec posts to save costs; so it’s worth a closer look. Jacksons mesh fencing employs at least two vandal-proof mechanical fixing points per clip.

View our Security Welded Mesh Fencing for Medium & High Security Sites

EuroGuard® Flatform Heavy SR1 Plus: Ideal for sites where improving perimeter security whilst maintaining visibility are concerns. Perfect for a range of medium-high risk sites including the utilities, energy or even the education sectors.

EuroGuard® Combi SR1: Constructed with heavy steel gauge wires combined with timber slats this system combines aesthetics and design with reinforced security measures.

Securi-Mesh® Plus SR2: Constructed with double layer 358 mesh panels which have small apertures to help reduce the ability to climb the system Securi-Mesh® Plus SR2 employs vertical steel clamp bars in the panel to post fixing which bonds the mesh layers together for improved rigidity

UHS Extreme Mesh SR3: Heavy gate wire welded mesh security fencing system double skinned for high level of security.

UHS Heavy Mesh SR3: Doubled skinned to provide a high level of security, designed for high security sites.

Top