Our other sites:

Wire mesh panels are increasingly popular due to their strength, installation speed, and versatility. They’re an ideal fencing solution for sites that require through-visibility as well as security and are available in a range of styles from light mesh for pet enclosures or residential sites, to heavy mesh suitable for high security and commercial use.

Different types of wire mesh panels

Lightweight yet strong and durable, wire mesh fencing won’t suffer damage from strong winds or rot. It also resists climbing, with minimal footholds, and the lack of a flat surface deters vandalism and graffiti. As it allows for plant growth, wire mesh panels are also aesthetically pleasing, supporting the growth of low-level shrubs or, if desired, thorny plants for additional security.

From light mesh used for keeping livestock safe to high security panels that can resist even determined intruders, the most common types of wire mesh panels include:

How securely are the mesh panels attached to posts?

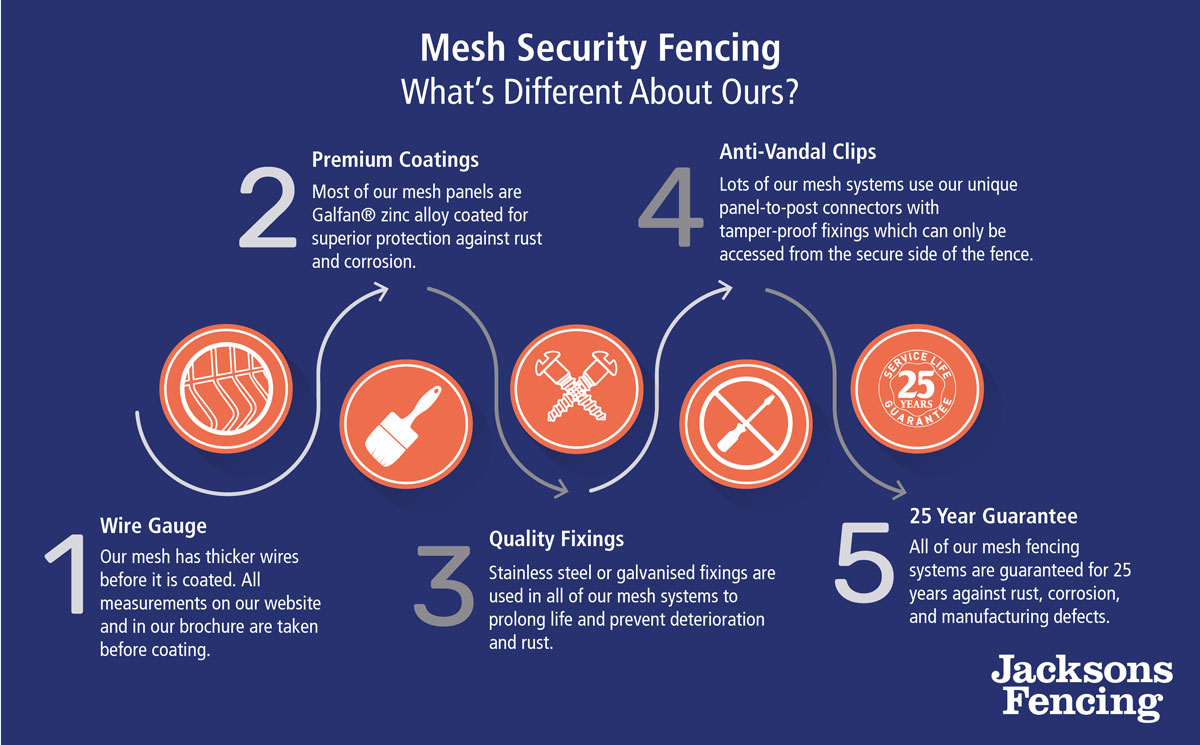

There are a number of ways that mesh panels are attached to posts, but not all ways are equal and there are key differences to be aware of that have an impact on the level of security the fencing system will provide. At Jacksons, we used tamper-proof bolts in all our welded mesh fencing systems to secure panels to posts, and the fixings are installed behind the fence line to prevent access to them. Many mesh fencing systems offer 'quick and easy installation' which sounds ideal, but this generally means these systems are also quick and easy to take down. They usually feature standard torx screws that can be removed with a standard DIY kit. Watch the video to find out more.

High quality steel that has been correctly coated

Every welded mesh panel begins as individual coils of steel wire; the wire should be a good grade and traceable back to an ISO 9001:2015-accredited source to ensure consistency and adherence to material and tolerance specifications.

The steel will then be galvanised or coated with a zinc alloy to protect it from rust and corrosion. An additional high quality polyester powder coating will further prevent unsightly cracks and chips forming and ensures the metal underneath is not exposed to weathering.

After being galvanised or coated in the zinc alloy, the mesh panel can then be colour coated. Dark green is commonly used as it blends into its surroundings, although for a primary school bold colours can brighten up a playground or, for commercial sites, it’s possible to print graphics or logos onto a mesh facade.

It’s important to check when the steel in a wire mesh panel has been coated, as this will determine the strength and longevity of the steel. Galvanised wire mesh should be galvanised after welding, as the welding process can remove the protective zinc coating. However, zinc alloy coated fencing can be welded after coating, as the higher aluminium content allows the join to ‘heal; under welding temperature and maintain protection against corrosion.

Wire gauge (diameter), posts and fixings

Measuring the wire gauge (the diameter of the steel) before it is coated is essential for accurate measurements. The coating will add thickness to the wire, but a smaller diameter wire with a heavier coating will not provide the same structural strength and resistance to cutting as a product with a heavier diameter wire. The type of coating can also affect the measurement if measuring after coating; hot dip galvanisation, for example, creates a thicker coating than a zinc alloy treatment.

Posts and fixings are integral to the safety and security of the fence, and should therefore be of the same standard as the wire mesh panels. Panel-to-post fixings should be tamper-proof and consist of at least two fixing points per clip to ensure the posts and fixings do not present a weak spot in the fencing.

Choosing wire mesh fencing

There is a wide range of wire mesh fencing available for a range of applications; a thorough site and risk assessment will help you better understand the appropriate fencing for your site.

For higher security requirements, Securi-Mesh (prison mesh), and Securi-Mesh Plus (double skin) offer excellent protection for residential and commercial sites. Their modern design, allowing for plenty of light and visibility, also make these varieties of wire mesh fencing an aesthetically-pleasing addition to contemporary designs.

EuroGuard® Regular and EuroGuard® Extra are both V-mesh fencing styles which offer rigidity and strength whilst also being an attractive option for lower-risk sites, such as schools and parks.

All our wire mesh panels and welded mesh fencing can be LPS 1175-security rated, and some versions can be approved for government use (CPNI). With over 70 years of experience, our experts are ready to help you specify the right wire mesh fencing for your requirements. To find out more about the range of security fencing styles and applications, contact our team today.

Read our related blog posts:

Related products

Jacksons Security has a range of products relating to this article, all complete with our 25 year service life guarantee. If you cannot find the item you are looking for, please do not hesitate to call our friendly sales team.

Related Content

Top